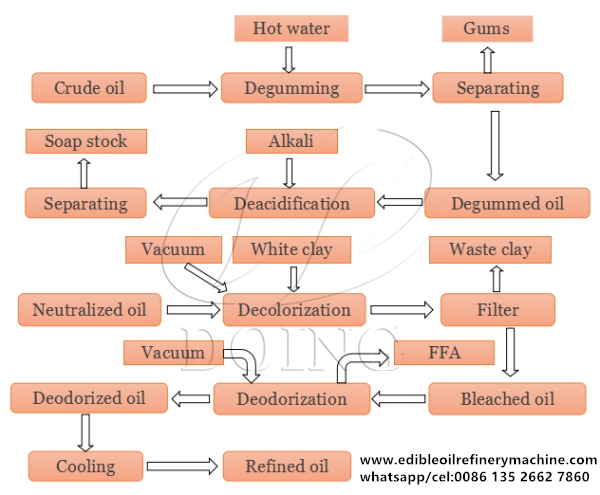

Edible oil refinery plant and edible oil refining process

Edible oil refining is a process to remove impurities that are contained in crude oil obtained either from expellers or solvent extraction plant, and improve the functionality of the oils. These impurities include Moisture, Solids, Gums, Free-Fatty Acids (FFA), Waxes, and Compounds of Sodium, Potassium, Magnesium, Calcium, and other metals.

However, modern consumers think color, odor and taste are impurities, too. All these impurities are removed in a series of steps: degumming (to remove gums), deacidification (to remove FFA), decolorization (to remove color), deodorization (to remove odor and taste), and dewaxing or winterization (to remove waxes).

Henan Doing Mechanical Equipment Co., Ltd's product range includes a wide range of edible oil refineries and vegetable oil refinery plant, which can be divided 1-20tpd batch type edible oil refining machine, 10-50tpd semi-continuous edible oil refinery plant and 30-1000tpd full-continuous edible oil refinery plant by type.

We can customize it for our customers according to actual calls to refine different kinds of crude edible oil, such as soybean oil, peanut/groundnut oil, sunflower oil, rice bran oil, corn oil, rapeseed oil, cottonseed oil, olive oil, palm oil, palm kernel oil, etc.

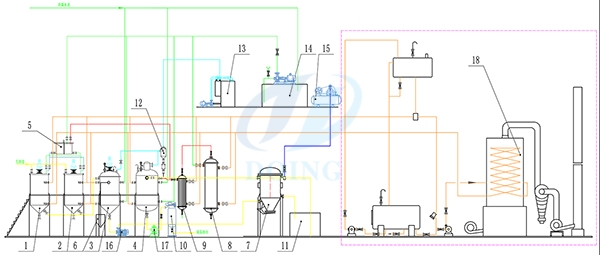

Batch type edible oil refinery plant (1-20tpd):

For capacity less than 20tpd, and when crude edible oil has F.F.A. content of 2 % or less normally, batch type edible oil refinery plant is recommended. Batch type edible oil refinery plant also called mini or small scale edible oil refinery plant is suitable for small tonnage processing, simple equipment, low investment, but can achieve the required parameters of refined edible oil, and a small footprint, low requirements for building height.

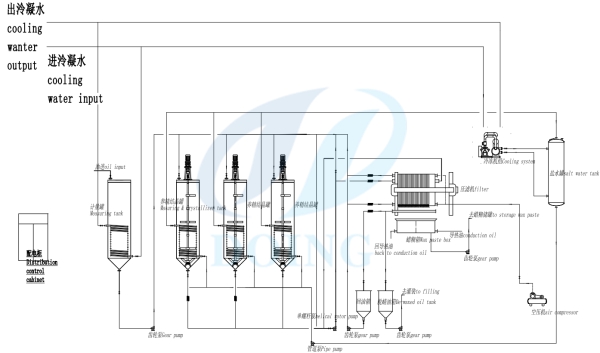

The flow chart of batch type edible oil refinery plant:

Batch type edible oil refining process flow chart(Click here for larger view)

Batch type edible oil refining process flow chart(Click here for larger view)

The functions of main equipment:

Neutralization pot: Remove the gum and acid in the crude edible oil through acid refining, alkali refining and water washing.

Decolorization pot: Remove pigments from neutralized oil by adsorption of white clay.

Deodorization pot: Use high temperature steam to remove the bad odor from the bleached oil.

Conductive oil stove: It is used to provide the heat for the whole batch type edible oil refinery.

Vacuum pump: Guarantee the vacuum environment of the deodorization pot.

Steam generator: Provide high temperature steam for the deodorization pot.

The advantages of Doing Company batch type edible oil refinery plant:

Small scale batch edible oil refinery plant

Small scale batch edible oil refinery plant

1. In decolorization section, to filter the waste white clay adopts a leaf filter, which is convenient operation, low labor intensity and good filtering effect.

2. The deodorization pot is made of stainless steel, which is resistant to corrosion and prevents metal ions from entering the edible oil.

3. Our edible oil refining process emphasizes energy conservation and the rational use of thermal energy.

[Recommended reading: Doing Company small scale edible oil refinery plant project cases--2TPD palm oil refinery plant in Liberia, 20TPD olive oil refinery plant in Peru.]

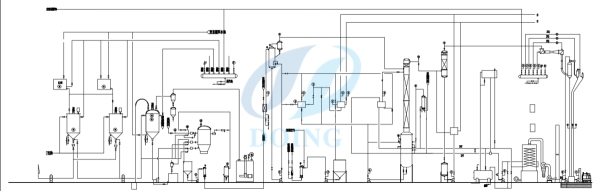

Semi-continuous edible oil refinery plant (10-50tpd):

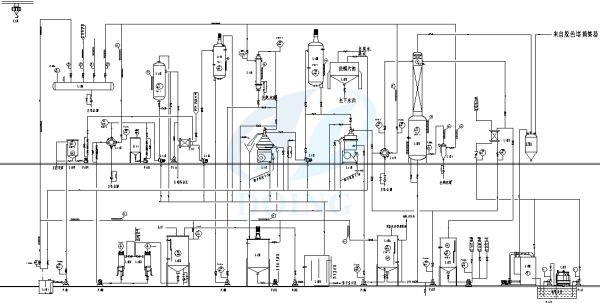

Actually, semi-continuous edible oil refinery plant is usually used in medium scale edible oil refinery plant, which has a little difference from batch type edible oil refinery plant. In semi-continuous edible oil refinery plant, the deodorization pot is replaced by the deodorization tower. So the acid refining, alkali refining, bleaching process are all still batch type, but the deodorization process is automatic.

If F.F.A. content of crude edible oil more than 5%, and you don’t want to get large quantities of soapstock, semi-continuous edible oil refinery plant is the best choice. According to the quality of your crude edible oil and the capacity (10-50tpd), our engineer can design suitable edible oil refinery plant for you.

The flow chart of semi-continuous edible oil refinery plant:

Semi-continuous edible oil refining process(Click here for larger view)

Semi-continuous edible oil refining process(Click here for larger view)

The advantages of Doing company semi-continuous edible oil refinery plant:

30tpd semi-continuous edible oil refinery plant

30tpd semi-continuous edible oil refinery plant

1. To refine the same quality crude edible oil, semi-continuous edible oil refinery plant can get more refined oils with good quality.

2. The operating cost is lower than batch type edible oil refinery plant. If the acid value of the crude edible oil is not very high, it is not necessary to add alkali to neutralize the acid. So the cost of alkali consumption can be saved.

3. The cost on labors is lower, because deodorizing part is automatic and does not require workers to operate.

[Recommended reading: Doing Company medium scale edible oil refinery plant project case--30TPD palm oil refinery plant in Congo.]

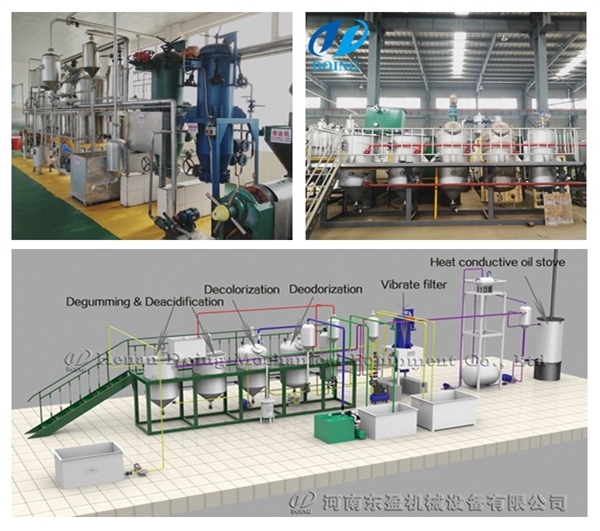

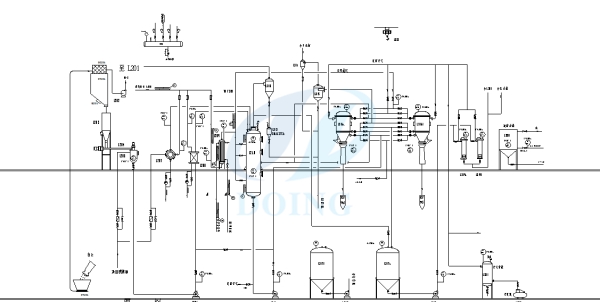

Full-continuous edible oil refinery plant (30-1000tpd):

General speaking, for 30tpd and above, the full-continuous edible oil refinery plant is much better for large scale edible oil refinery plant. Though the cost of full-continuous edible oil refinery plant is high, the quality is much more steady and average. The whole edible oil refining process is totally automatic, which only need five persons to operate. There are more equipment in full-continuous edible oil refinery plant, and the refining process is more complicated.

Main equipment in full-continuous edible oil refinery plant:

Machines in full-continuous edible oil refinery plant

Machines in full-continuous edible oil refinery plant

Crude oil filter, Crude oil tank, Crude oil pump, Washing centrifuge, Degumming centrifuge, Vacuum dryer, Hot water tank, Soap-stock tank, Decolorization tower, Decolorization oil pump, Plate filter, Steam super-heater, Decolorized oil tank, Deodorization tower, Deodorization oil pump, Vacuum system, Vacuum pump, Cooling tower, Thermal oil furnace, PLC automatic control

The working process of full-continuous edible oil refinery plant:

Full-continuous edible oil refining process

Full-continuous edible oil refining process

Main advantages of full-continuous edible oil refinery plant:

1. Suited for high-capacity lines (low space requirement);

2. Input/output heat recovery;

3. Simple automation and control;

4. Low manning level.

[Recommended reading: Doing Company large scale edible oil refinery plant project case--100TPD palm oil refinery and fractionation plant in Kenya.]

The detailed introduction of each part in edible oil refining process is as following, please keep on reading.

Degumming and Deacidification process:

Degumming and Deacidification process flow chart(Click here for larger view)

Degumming and Deacidification process flow chart(Click here for larger view)

1. Pre-heating: Pumping crude edible oil into oil refining tank, stirring quickly, and simultaneously heating by steam or heat-transfer oil (in plate pipes).

2. Hydration degumming: Adding hot water while you should manage the water amount, temperature and water adding speed.

3. Neutralizing section: Adding alkali to remove FFA. Traditionally, FFAs are treated with caustic soda (NaOH). At the end, the soaps got from reactions are separated from the oil.

4. Washing section: About 500 ppm soaps still remain in the separated neutralized oil, adding 5% of hot water to reduce the residual content of soaps,because hot water will absorb oil soap and other impurities.

Different crafts will adopt different separating methods. For batch type edible oil refinery plant and semi-continuous edible oil refinery plant, they will adopt precipitation separation method, full-continuous edible oil refinery plant will adopt centrifuge separation method.

Some customers prefer not to perform caustic neutralizing. Instead, they prefer Physical Refining in which the FFAs are evaporated from the oil under high temperature and vacuum. This process can be combined with deodorizing process in deodorization tower of semi-continuous and full-continuous edible oil refinery plant.

Why Physical Refining process is preferred?

(a) It does not produce soaps;

(b) It recovers fatty acids that provide better cost recovery;

(c) There is smaller yield loss compared to caustic refining—especially for oils with higher FFAs;

(d) It is a chemical-free process.

Related read: What is physical refining of edible oil?

Decolorization process:

Decolorization process flow chart(Click here for larger view)

Decolorization process flow chart(Click here for larger view)

Decolorization, also called bleaching, is to remove color pigments contained in Neutralized Oil. Usually, with Bleaching Clay adsorb the color pigments.

1. Vacuum drying section:

Neutralized Oil after washing, still contains a small amount of water. Neutralized oil was heated to about 105 degrees in vacuum drying tower to dehydrate, then drying oil is pumped directly into the bleaching pot/tower.

2. White clay a bsorbing section:

At a mix ratio(1%-3%), add white clay into oil. Bleaching tower has several layers, and each layer is equipped with a steam ejector, which is used for mixing oil and clay. In this section, the residual soap in the oil, gum precipitation, plastid and other metals are all absorbed by the white clay.

3. Filter section:

After lowering the bleached oil temperature, pump the oil and clay mixture into vibrating filter to remove the waste the waste clay, and the decolorization process is finished.

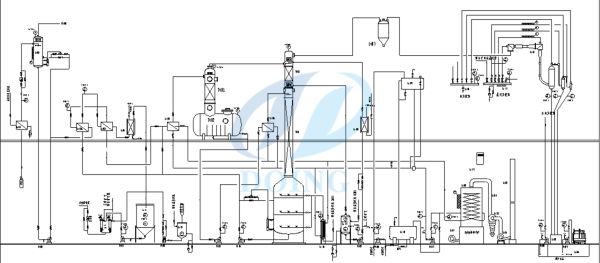

Deodorization process:

Deodorization process flow chart(Click here for larger view)

Deodorization process flow chart(Click here for larger view)

Generally speaking, deodorization process is the final stage in edible oil refining process. The decolorized oil is subjected to steam distillation under condition of high temperature and vacuum to remove bad smell, free fatty acids and other undesired minor components.

1. Deoxygenation section:

The decolorized oil came from filter machine contains a little oxygen, which should be removed before pumping the decolorized oil into deodorization tower/tank. The machine used to deoxidize is called deaerator.

2. Heating section:

In batch type edible oil refinery plant, pumping and heating the decolorized oil in deodorization tank, when the temperature reaches above 100℃, inject the high-temperature steam. But in semi-continuous and full-continuous edible oil refinery plant, the decolorized oil is through a series of heat exchangers and heated to about 250-260℃. In heating process, part of free fatty acids with low boiling point and some volatile matter are evaporated out, and then gas and liquid oil enters into the padding type deodorization tower from different entrances.

3. Deodorization section:

The high-temperature steam bring the odors away. At the meanwhile, the dehydration process of the 0.5% moisture in oil is also finished at this step. In full-continuous edible oil refinery plant, there are other sections, such as fatty acid recovery section. The distillate is collected in a fatty acid storage tank for recycling.

4. Cooling section:

The cooling of deodorized oil can be finished at the original tank, also can be cooled in vacuum cooking tank. Stop heating and turn down the steam, and when the temperature of oil nearly 80℃, turn off the steam.

5. Filter section:

If your edible oil needn’t dewaxing and fractionation, pump oil to safety filter for removing small impurities, then get refined edible oil.

Dewaxing/ winterization process:

Dewaxing process flow chart(Click here for larger view)

Dewaxing process flow chart(Click here for larger view)

Dewaxing/ wintwerization is a process in which higher melting point parts of edible oil like waxes or triglycerides will precipitate through slowly cooling and crystallization, and then use filtration or centrifugation way to remove these substances.

Mostly, dewaxing process is applied to rice bran oil, corn germ oil, sunflower oil, cottonseed oil which has a high content of waxes, fatty acids and lipids. Because waxy substance in the edible oil reduce the transparency and digestibility of the oil, and change its taste and palatability.

Wax content of different kinds of edible oil:

| Edible oil | Rice bran oil | Corn germ oil | Sunflower oil |

| Wax content(%) | 3-9 | 0.05 | 0.01-0.35 |

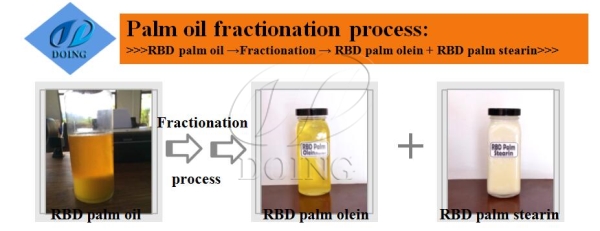

Fractionation process:

Fractionation differs from winterization. Though with same operation principle, the purpose is different. Winterization is to remove higher melting point triglycerides of edible oil, which is usually regarded as a part of edible oil refining. However, fractionation is a process of edible oil modification, which involves the change of edible oil composition. Palm oil and palm kernel oil require fractionation process to get olein and stearin.

Plam oil fractionation process

Plam oil fractionation process

1. Break the crystals: Pre-heat to break the crystals in palm oil, whose purpose is to make crystallization more evenly.

2. Crystallization and crystal growing: Cool down the palm oil slowly with a certain gradient, and the crystals grow out, form into crystal nucleus, become larger gradually.

3. Filter: Crystallized RBD palm oil is conveyed to filter. Olein(liquid fat) will flow out to soft fat tank, and stearin will be unloading from the plates.

FAQ:

1.How many refined edible oil will I get after edible oil refining process?

Main factors influence the yield of refined edible oil:

1) Alkali refining loss

This is the loss in removal of gums, free fatty acid, moisture and impurities in crude edible oil.

2) Decolorization loss

This is because waste white clay absorb oil.

3) Deodorization loss

During deodorization process, the volatilization of fatty acids, small molecules such as aldehyde and ketone, sterols, vitamin E, etc and spatter loss of oil during stripping.

4) Loss of running, dropping, leakage or other phenomena caused by improper operation or equipment during production. Such losses should be avoided as far as possible.

For the details, please read: How to calculate the loss of refined edible oil?

2.How about the quality of refined edible oil that I get after refining?

There are many factors that influence the quality of refined edible oil.

1) The type of edible oil refinery plant you choose. Under the same conditions, the quality of refined edible oil processed by full-continuous edible oil refinery plant is best because of the high edible oil refining technology.

2) The quality of your crude edible oil. With the same equipment and the same operation, the worse the crude edible oil quality is, the worse the refined edible oil quality is.

3) Failure to operate as required also affects refined edible oil quality.

For the details, please read: Which grade of edible oil can I get after refining process?

3.How about the production consumption in edible oil refining process?

1) Different kinds of crude edible oil need different refining technology, so the production consumption is also different. For example, high acid palm oil need more alkali to neutralize free fatty acids.

2) The quality of your crude edible oil. With the same equipment and the same operation, the worse the crude edible oil quality is, the more production consumption there is.

3) The capacity and types of your edible oil refinery plant.

4) Other factors(Operation process, etc.)

Leave a message

If you wanna to get more details about ProductWinterization/fractionation/dewaxing, you can send E-mail to market@doingoilmachine.com . Or you can consult our professional engineers and specialized sales team by leaving a message in below form. We will contact you ASAP. You also can visit our factory in Henan, China.